We are reader-supported. When you buy through links on our site, we may earn an affiliate commission.

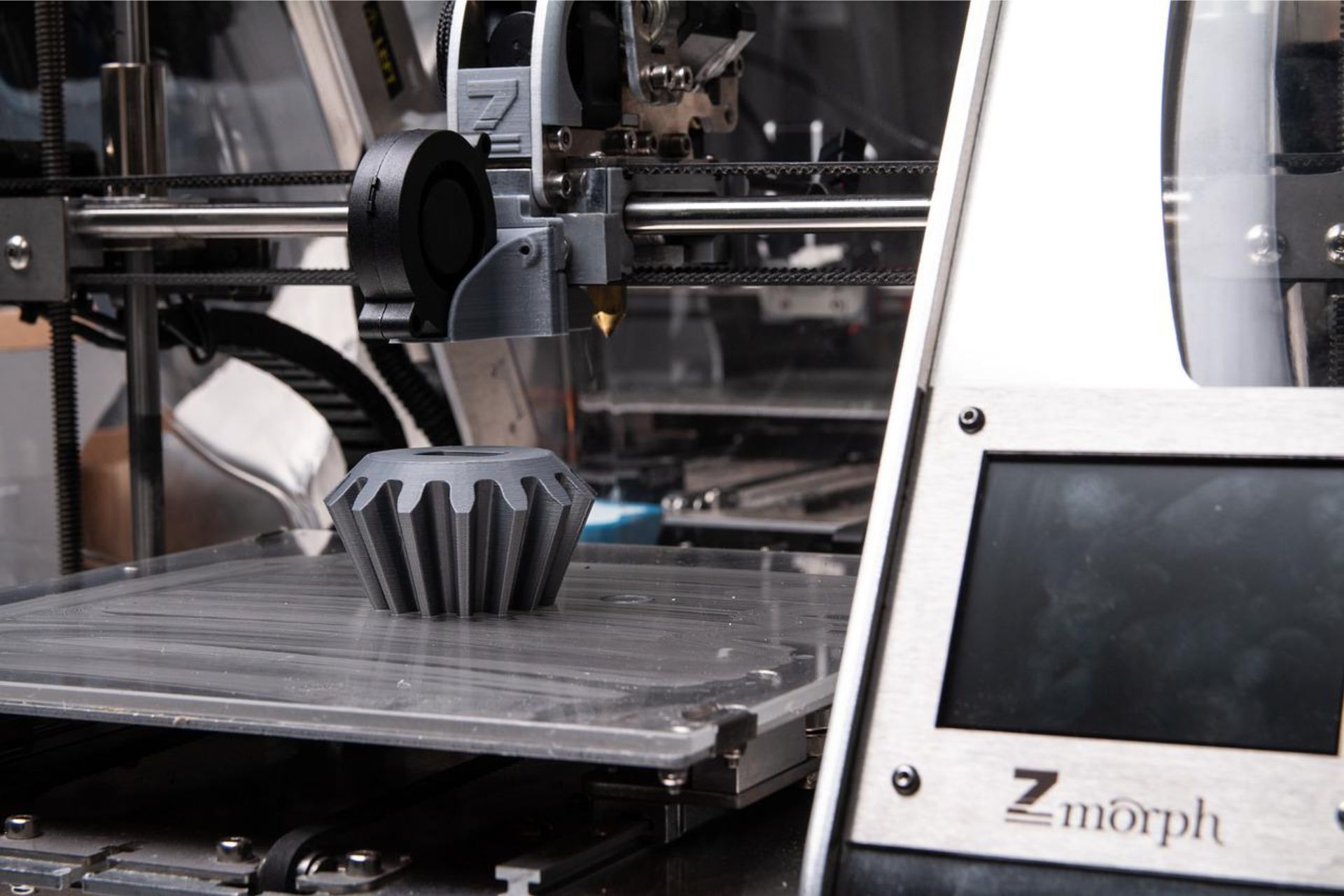

Digitalization and the sustainability movement are impacting the construction industry. Builders are using advanced machinery to improve the efficiency, sustainability and safety of projects. They may use 3D printers to enhance the stability and longevity of structures.

In the past decade, engineers advanced 3D printing technologies. Today, the technology is more cost-effective and accessible. Construction professionals predict digitalization will define the industry’s future.

What is 3D Printing Construction?

Individuals use 3D printing in construction to minimize errors and enhance the sustainability levels of structures. Printers can make three-dimensional building materials from digital files. 3D printers may also lay the materials on site to support construction automation.

Some organizations use 3D printers to build affordable housing. For instance, Icon, a Texas-based company, created community housing for individuals earning $3 or less a day. Companies also use 3D printing in construction to meet environmental conservation goals.

The Demand for 3D Building

Eco-consumers are influencing the construction industry. Conventional construction practices produce adverse environmental effects. The industry generates nearly 27% of global greenhouse gas emissions.

Countries are establishing green building standards to challenge atmospheric and surface-level pollution. America’s National Green Building Standard reduces adverse environmental and health effects in the construction industry. It uses a rating and certification system to monitor pollution.

Reducing construction pollution is essential to minimize volatile organic compound (VOC) pollution. Some building materials release VOCs into the environment and produce ground-level ozone. The ozone creates smog, which interferes with the health of species and humans.

Other manual construction practices increase stormwater runoff, which carry toxins to the ocean. Nitrogen- and phosphorus-rich contaminants promote algal blooms and deplete aquatic oxygen levels. Builders can use 3D printers to conserve local ecosystems.

3D Printing Construction Techniques

There are a few different ways builders use 3D printing in construction. The first technique is concrete production. Individuals are automating concrete development to increase efficiencies and decrease environmental effects.

Construction professionals use nearly 4 billion tons of concrete annually. 3D printing concrete can minimize material waste and improve a structure’s efficiency. Builders also use a robotic arm extruder to apply 3D printed materials onsite.

Building professionals can also automate metal production with 3D printers. Advanced machines use a gas-filled chamber to oxidate and heat metal powder. Then, a scanner moves across the material and fuses metal particles together to increase its strength.

Many construction professionals are integrating 3D technology into their building practices. The technology offers various environmental, financial and safety benefits.

The Benefits of 3D Printing in Construction

3D printers produce less waste in the construction sector, which minimizes greenhouse gas emissions and landfill pollution. They also help builders save money on projects. Reducing material waste and increasing building efficiency can significantly reduce construction costs.

Using 3D printing in construction also increases job site safety. Building on elevated surfaces and material mixing can cause health and safety risks. 3D printing reduces hazards and may decrease insurance costs.

Another 3D printing benefit involves design flexibility. Builders create unique architectural features using onsite material production. Construction professionals can also improve onsite sustainability measures using modular building techniques.

Pairing with Modular Construction

Individuals may pair 3D printing with modular construction to decrease waste and greenhouse gas emissions. Modular construction occurs offsite in a monitored facility. Professionals develop buildings in various parts using recycled materials.

Also, many modular construction facilities also have carbon capturing systems to minimize atmospheric degradation. The technologies capture and filter surface-level emissions before they pollute the environment. Pairing modular construction with 3D printing can also increase building efficiencies.

Construction professionals can produce structures in three to four weeks using the modular development method. Individuals may additionally prevent hazards using modular construction techniques. Building sections in controlled environments reduce individuals’ exposure to falling materials and air pollutants.

Reducing builders’ exposure to emissions can protect their lung health. Individuals’ risk of developing lung cancer, asthma and other fatal respiratory illnesses increases when inhaling emissions. Reducing emissions also supports sustainability-enhancement efforts.

LEED Certification

Government officials in different states are holding builders responsible for construction site pollution. Professionals developed the Leadership in Energy and Environmental Design (LEED) certification program to determine a structure’s sustainability. LEED is the most commonly used green building evaluation system globally.

Structures with LEED certifications release fewer greenhouse gas emissions and conserve natural resources. They also consume about 25% less energy than conventional structures. The buildings also reduce municipal solid waste (MSW).

The Future of 3D Printing in Construction

In summary, researchers believe 3D printing will define the construction industry’s digitalization. Building practices may become more automized as 3D printer prices decrease. Engineers are also developing more accessible and cost-effective printers to support sustainability efforts in the construction sector.