Can Self-Healing Materials Change the Construction Industry?

We are reader-supported. When you buy through links on our site, we may earn an affiliate commission.

The construction industry is no stranger to self-healing materials. However, a new breed of living building solutions may change the game, allowing stakeholders to cut costs, mitigate the impact of the labor shortage and design environmentally conscious structures.

Self-Healing Materials Versus Living Materials

Self-healing and living materials aren’t mutually exclusive. Still, these terms aren’t always interchangeable.

A construction material is self-healing when it can detect structural flaws and fix the damage without intervention. On the other hand, a living building material incorporates microorganisms into the manufacturing process. Self-healing is only one of their unique capabilities — they may also multiply, remove toxic substances from the air and trap carbon dioxide.

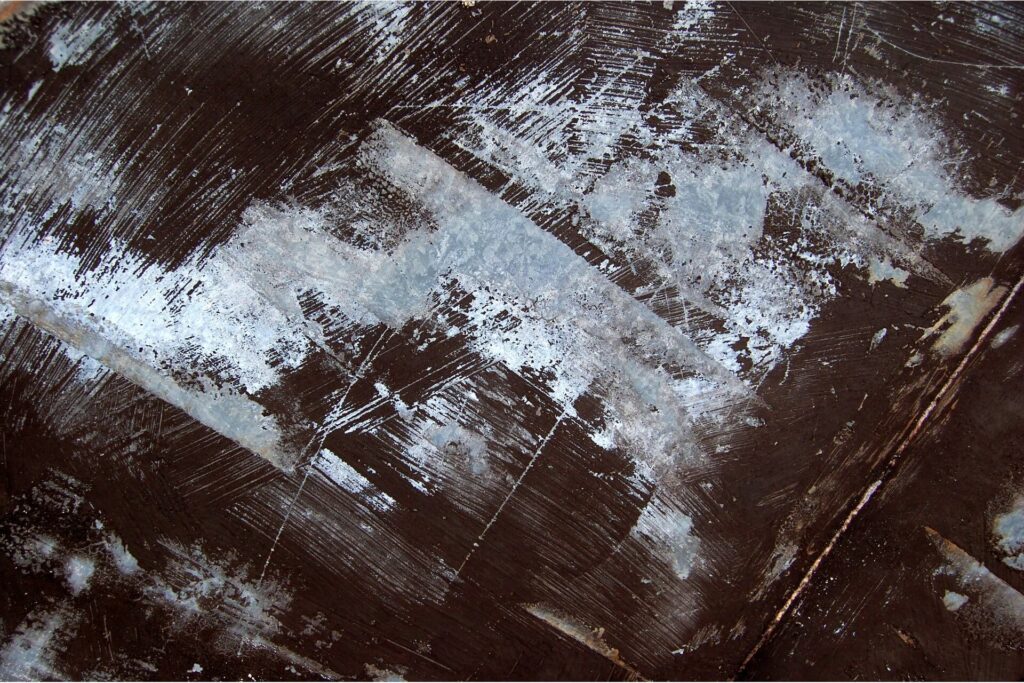

Galvanized steel is an example of a self-healing material that isn’t living. This iron alloy has a zinc coating that seals damaged areas to prevent further corrosion by automatically forming a protective layer made of zinc oxide and zinc carbonate.

Self-healing living building materials also work like that, except they use specific fungi and bacteria to sense and repair structural imperfections independently. Other self-healing materials have plant cells and mimic how vegetation grows using CO2.

Can Self-Healing Materials Change the Construction Industry?

Self-healing materials can improve the construction industry and address its pressing problems.

These cutting-edge materials can simplify the upkeep of structures, saving money over the long term. Less demand for infrastructure maintenance and repairs — at a time when the industry deals with acute talent scarcity — allows construction companies to manage their limited staff better.

Regarding sustainability, self-healing building solutions can help decarbonize the industry. They can replace heavily used conventional materials with high embodied carbon — like concrete, whose primary ingredient emits 0.9 ton of CO2 during manufacturing for every ton produced.

Chemists and materials scientists researching green construction innovations tackle waste reduction. These experts aim to develop solutions to sense 100% of the damage and regenerate quickly and efficiently. These advanced materials can also be deconstruction-friendly and biodegradable.

Properties made with self-healing materials can be climate-resilient. They may never rely on virgin or recycled resources to fix structural flaws and begin reconstruction immediately upon damage detection.

3 Most Promising Self-Healing Construction Materials in the Works

Research on self-healing building solutions is left and right. In terms of potential, these three take the cake.

1. Mycelium-Wood Composite

In June 2023, researchers at the Delft University of Technology in the Netherlands — led by Dr. Kunal Masania — started a five-year project to explore the potential of biological organisms for developing living composites for lightweight engineering structures. Less than two years in, their work has already yielded exciting results.

Masania and company have focused on mycelium — a fungal root-like structure that can grow an expansive sensing network of fibers. Building a vast mycelial network throughout the construction material only takes a few cells.

The team has immediately made inroads in producing a three-dimensional composite of living fungal cells and wood. Masania’s experience in combining hydrogels with the fungus Ganoderma lucidum to initiate mycelial growth on lattice structures through 3D printing has come in handy.

Masania’s work centers on fungi — resilient organisms that can survive in the harshest conditions and are relatively painless to grow. Plus, most have a vegetative, filamentous branching component. G. lucidum is the darling of materials scientists because its mycelial network lends self-assembly, sensing, self-healing, dry climate tolerance and many other distinct properties to engineered living materials.

2. Biocement

University of Colorado Boulder Living Materials Laboratory head Dr. Wil Srubar and his team have invented biocement using cyanobacteria. The researchers found that these microbes can grow and make limestone — the same output self-healing concrete produces when it gets wet — using CO2 when introduced to a sand-and-gelatine solution under humid conditions.

Bricks made of these microorganisms can dramatically reduce the mammoth greenhouse gas emissions associated with cement manufacturing. They may also act as carbon sinks since they sequester CO2.

3. Plantlike Polymer

Chemical engineers at the Massachusetts Institute of Technology have designed a synthetic substance called glucose oxidase — a mix of glucose and aminopropyl methacrylamide. It can build itself with exposure to CO2 from the air and sunlight, just as plants do.

This material behaves this way because it uses spinach chloroplasts, chlorophyll-containing components within plant cells that absorb light, to catalyze the chemical reaction between CO2 and glucose. This gel-like substance is too weak to become a construction material but strong enough to function as a sealant or coating. Further research is necessary to make composites out of it.

However, the chloroplast is only a placeholder due to its instability. The researchers plan to replace it with nonbiological catalysts so the material can behave as intended for much longer.

Although this self-healing material has kinks that need ironing out, this breakthrough demonstrates that it’s possible to convert urban jungles into forests. A substance not derived from fossil fuels that can turn the most prevalent greenhouse gas into a stable, solid form is perhaps the most sustainable solution to climate change the construction industry could ever have.

The Future Belong to Self-Healing Construction Materials

Building structures with eco-friendly materials that require little maintenance is now less of a pipe dream. When they’re ready for prime time, the construction industry’s rapid decarbonization would be a sight to see.